Outdoor HVAC Airflow Measurement

Proper outdoor HVAC air flow measurement is crucial for commercial building airflow measurement and control. Outside air is necessary to maintain indoor air quality, as well as overall energy efficiency and the health and long-term performance of the building.

Outside air is used by HVAC systems to refresh the air inside today’s high-performance buildings. Accurate measurement is essential to ensure that the minimum outdoor air intake standards of the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) are met, energy consumption calculations are accurate, and that healthy indoor air quality is maintained. This last requirement has become even more important since the COVID-19 pandemic.

However, choosing a metering technology for accurate outdoor airflow measurement can pose a challenge due to a lack of straight runs on outdoor HVAC installations, highly variable airflow velocities, high moisture content, and the presence of airborne contaminants at the point of measure.

Outdoor Air Measurement Technologies

Manufacturers of airflow monitoring equipment have typically used either thermal dispersion technology or Pitot arrays for measuring the ventilation rates of outdoor air in HVAC systems. However, these approaches both have limitations. For example, thermal sensors do not tolerate any form of moisture in the air and they perform poorly in dynamic and turbulent airflow conditions such as the windy rooftops of commercial buildings.

Pitot arrays with differential pressure (DP) transmitters can be effective in outdoor air measurement systems. However, these systems also have trouble performing accurately in windy airflow conditions. And lower-cost DP systems incorporating fewer arrays may not be able to maintain accuracy without periodic maintenance and calibration.

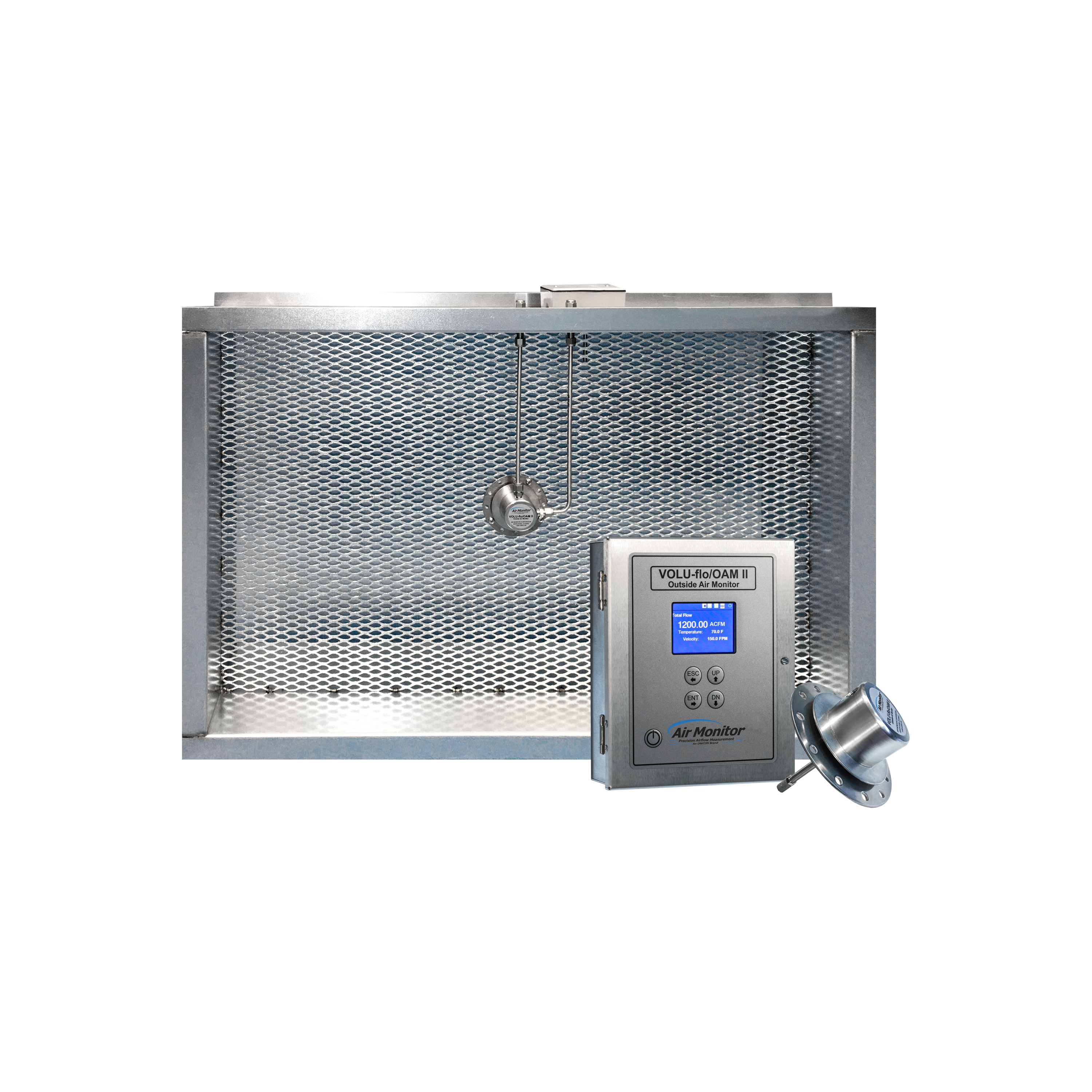

Air Monitor’s outdoor airflow measurement solution, the OAM II, uses a third approach, which relies on measuring the pressure difference across a known resistance. The small differences in static field pressures created by air moving through a fixed inlet allow the OAM II to accurately measure airflow without the need for straight ducts to condition the flow.

The OAM II is specifically designed to overcome the many difficulties of obtaining accurate measurements of outside airflow:

Accurate air flow measurement with limited straight duct runs

Specifically designed for outdoor HVAC systems, Air Monitor’s Outside Airflow Measurement system (OAM II) accurately measures flow across a fixed inlet, such as a louver, screen, or layer of expanded metal. This minimizes the need for straight duct runs to condition airflow before measurement.Measurement of variable airflow rates and low air flow

Air Monitor’s OAM II outdoor airflow measurement technology is equipped with a patent-pending uni-sensor system that is unaffected by gusting wind. This allows for accurate measurement of the differential pressure created by the variations in airflow entering and moving through the inlet.Overcome the presence of airborne contaminants and moisture

The OAM II uni-sensor design eliminates measurement instability caused by the presence of moisture. It also prevents accuracy degradation due to the build-up of dust and debris deposits from outside air that can affect other sensing technologies.OAM II Outdoor Airflow Measurement System & Airflow Measuring Station

Air Monitor’s AMCA-certified OAM II has been specifically engineered to overcome the challenges associated with measuring outdoor air intake for HVAC systems. The OAM II can be configured for use with most single, dual, and split inlets found on air handlers and built-up systems.

Each OAM II consists of a dedicated transmitter with a built-in barometric pressure sensor, reference temperature sensor(s), and uni-sensor flow element(s).

OAM II Airflow Stations ease installation and commissioning by factory mounting sensors onto a layer of expanded metal of known fixed resistance welded into a galvanized sheet metal casing. In many applications, the known fixed resistance of the OAM II Airflow Station allows the overall system to be pre-calibrated at the factory for plug-and-play operation.

Benefits of the OAM II include:

- High tolerance for dynamic variations in velocity and direction caused by wind gusts

- High accuracy in outdoor weather and climate conditions, such as changes in temperature and atmospheric pressure

- Output in the form of either actual flow rate (ACFM) or standard flow rate (SCFM)

- Requires zero straight run of duct for accurate measurement

- High turndown rate even with stacked transducer arrangements

- Robust construction that is impervious to dust and moisture

- Technology that can easily be applied in a variety of configurations and retrofitted to existing HVAC systems.