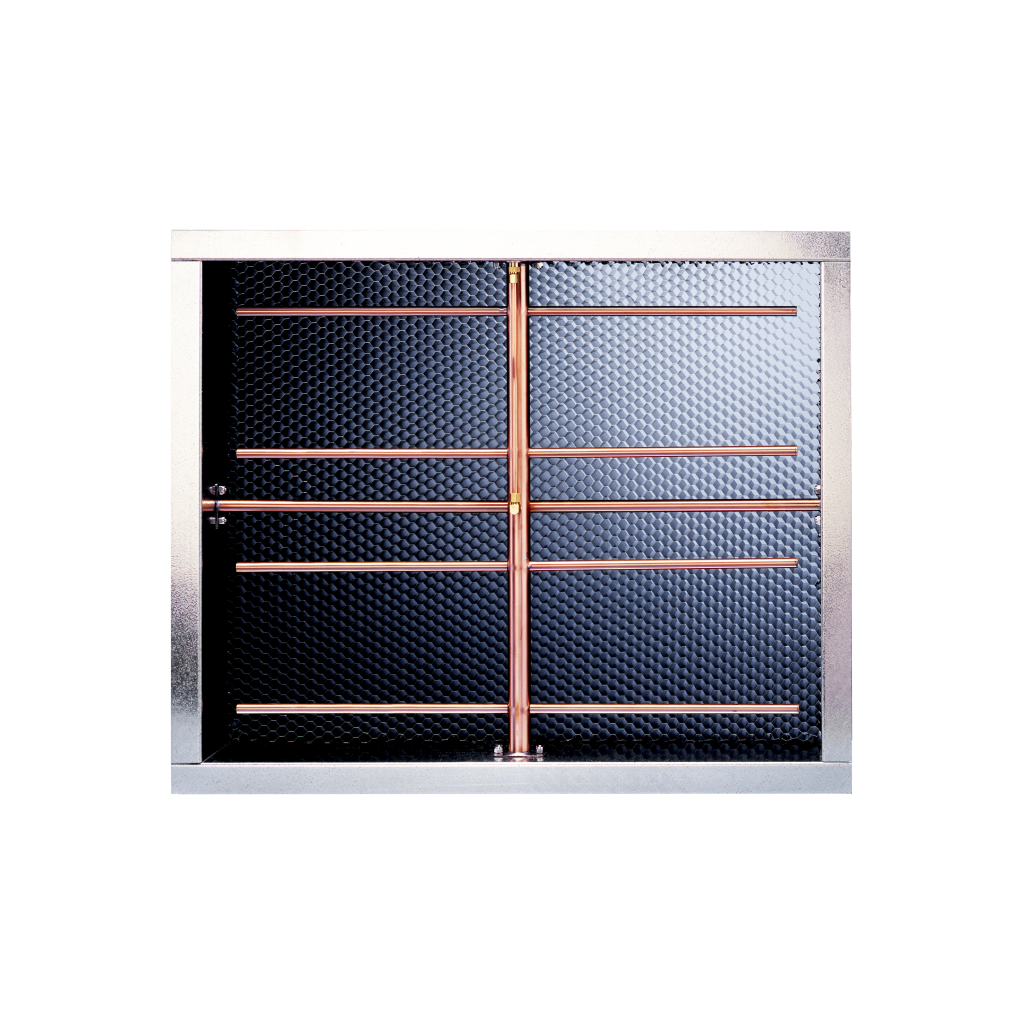

FAN-E Pitot Airflow Measurement Station

The FAN-E Station is a multi-point, self-averaging Pitot traverse station with an integral air straightening honeycomb cell. It’s capable of continuously measuring fan discharges or ducted airflow with a certified accuracy of ±2% when tested according to AMCA Standard 610. The high degree of accuracy is a result of the sensor locations and sensing ports, the honeycomb airflow processing and the instantaneous pneumatic averaging of multiple pressure values. The FAN-E Station is designed for applications with very limited straight duct runs and/or highly disturbed airflow. Patent No. 3,748,901.

Product Type: Flow Measuring Station with Flow Conditioner

Technology Type: Pitot Airflow Measurement Traverse Station

Applications:

- — Dirty Airflow processes:

- — Dust Collection Systems

- — Paint Spray Booths

- — Rotary Drum Dryers / Coaters

- — Fluidized Bed Dryers / Coaters

- — Clean Airflow Processes:

- — Clean Room Pressurization

- — Semiconductor

- — LCD Glass

Air Monitor Best in Class Value Proposition:

• Industry leading accuracy for airflow measurement.

• Shortest straight run requirements in the industry.

• Non-uniform flow profile problem solved: highest density of sensing point + patented measurement technology = excellent airflow measurement accuracy.

• Dirty airflow applications are no problem with AUTO-purge III feature.

• Excellent long-term stability, repeatability, and unmatched accuracy when used with Air Monitor’s family of flow computers featuring Auto-zero circuitry.

• Available Field Start Up Services.