Industrial Flow Measurement Solutions

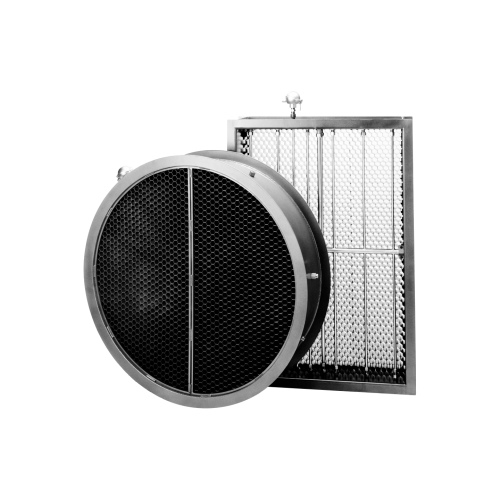

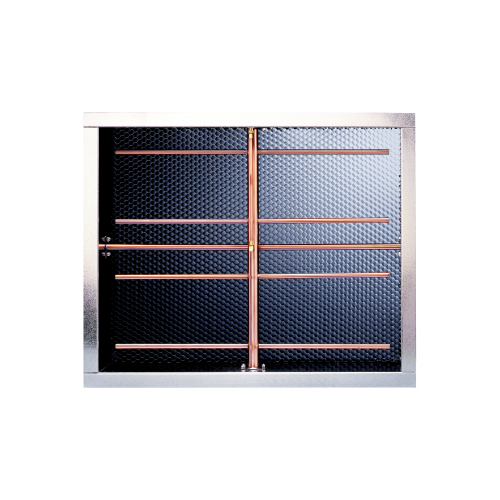

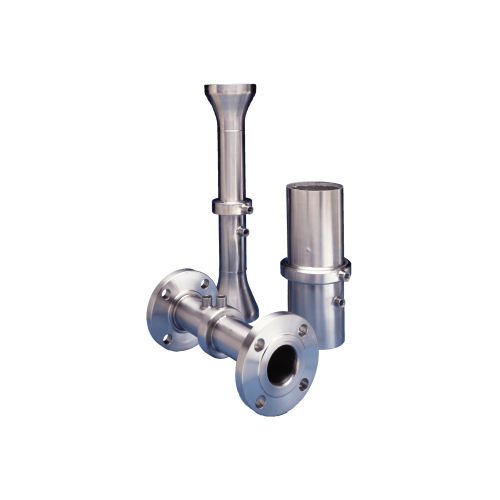

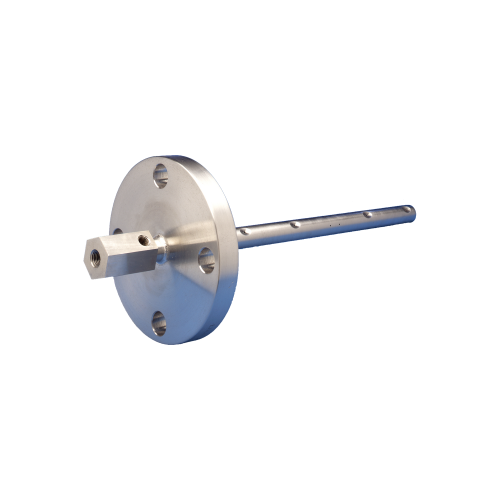

The Air Monitor flow measurement system is the most accurate low velocity, large duct capable flow meter in the world. Air Monitor provides engineered industrial flow measurement solutions by customizing systems and materials for the needs of the project.

Check out Air Monitor’s Best in Class Propositions:

- – Best accuracy in the industry in low flow, large duct applications.

- – AMC transmitters can measure lowest DP in the industry.

- – As little as zero straight run required.

- – Non-uniform flow profile problem solved – flow conditioners plus cross duct, multiple measurement points = excellent large duct measurement accuracy.

- – Dirty applications are no problem with AUTO-purge III feature.

- – Excellent stability, repeatability and accuracy with Auto Zero feature.

- – Available Field Services