The efficiency of industrial boiler systems can be maximized by tightening the control over the air-to-fuel ratio in the burners. Increased effectiveness in monitoring and controlling airflow in these systems makes tighter control possible. But which combustion control systems offer the best solution for efficiency improvements?

Combustion Control Challenges

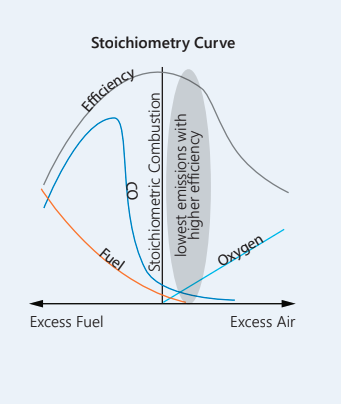

The objective of combustion air control is to minimize excess air without creating a fuel-rich environment that ultimately could lead to an explosion. A small level of excess oxygen is desirable to prevent calamity and to ensure complete combustion, so as not to waste fuel. However, a larger excess of air/oxygen also degrades the combustion efficiency because exhaust gas leaving the system at an elevated temperature also represents a loss of energy.

A common margin of excess oxygen is about 2-4% as a target to maximize efficiency and minimize formation of NOx, while still ensuring complete combustion of fuel. However, effectively and accurately monitoring airflow to maintain this small excess margin in industrial combustion systems is more complicated than monitoring the fuel flow.

For better boiler control, maintaining a balanced fuel and air mixture can be accomplished in a couple of different ways.

Parallel Positioning (PP) Systems

In a parallel positioning system, the objective is to link the position of the air damper with the position of the gas valve to maintain an acceptable air-to-fuel ratio that is based on a process setpoint, such as a required steam pressure.

In this type of cross-limiting system, the damper/valve controls are physically linked, so it is not possible to control fuel flow and airflow individually. PP systems may work reasonably well initially but will drift away from the desired fuel-air ratio over time as valve seals and damper linkages wear.

Additionally, a PP system will not respond to fluctuations in process temperature, duct static pressure, and barometric pressure changes, which alter air density and affect the air-fuel ratio.

Adding O2 Trim to PP Systems

A second option for airflow control is known as parallel positioning with O2 trim. In this control scheme, O2 trim systems are used to continuously monitor the amount of oxygen in the exhaust gas and provide feedback to an automatic positioner for the air damper.

The objective is to “trim” the airflow to drive excess oxygen lower (closer to 2-4% excess O2). PP with O2 trim is the most common type of control that is applied to combustion systems across many industries.

Fully Metered Combustion Air Control Systems

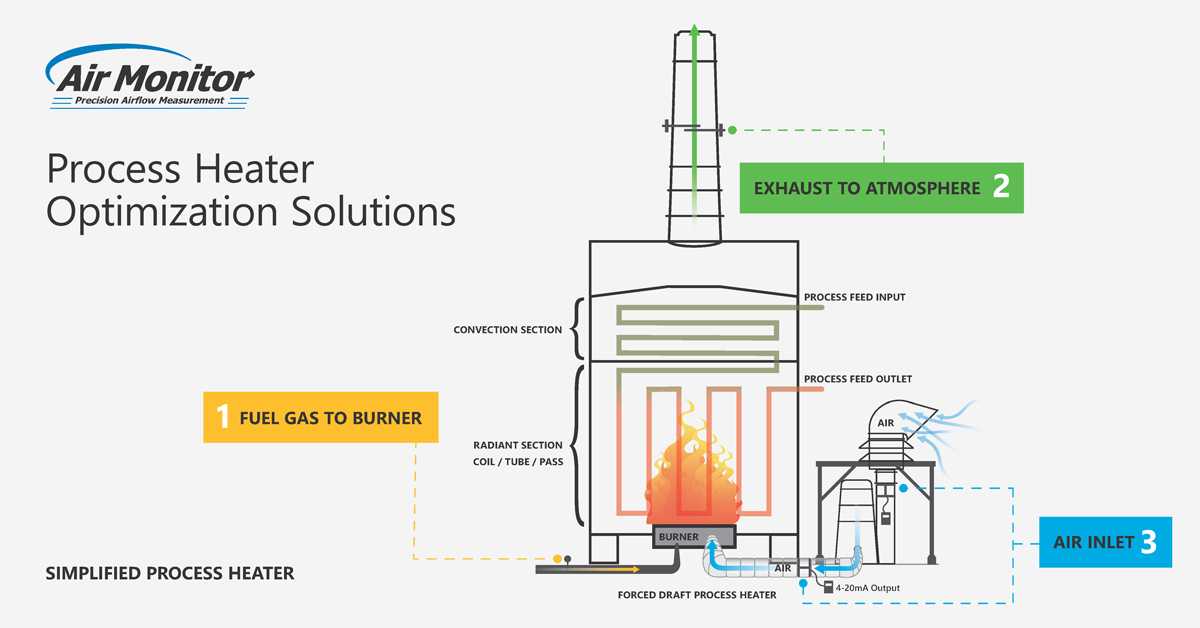

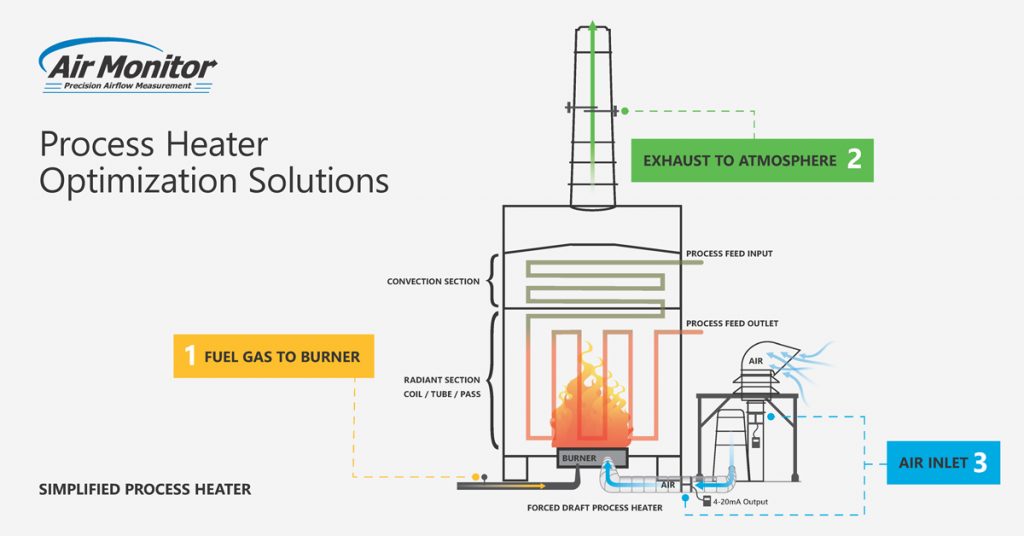

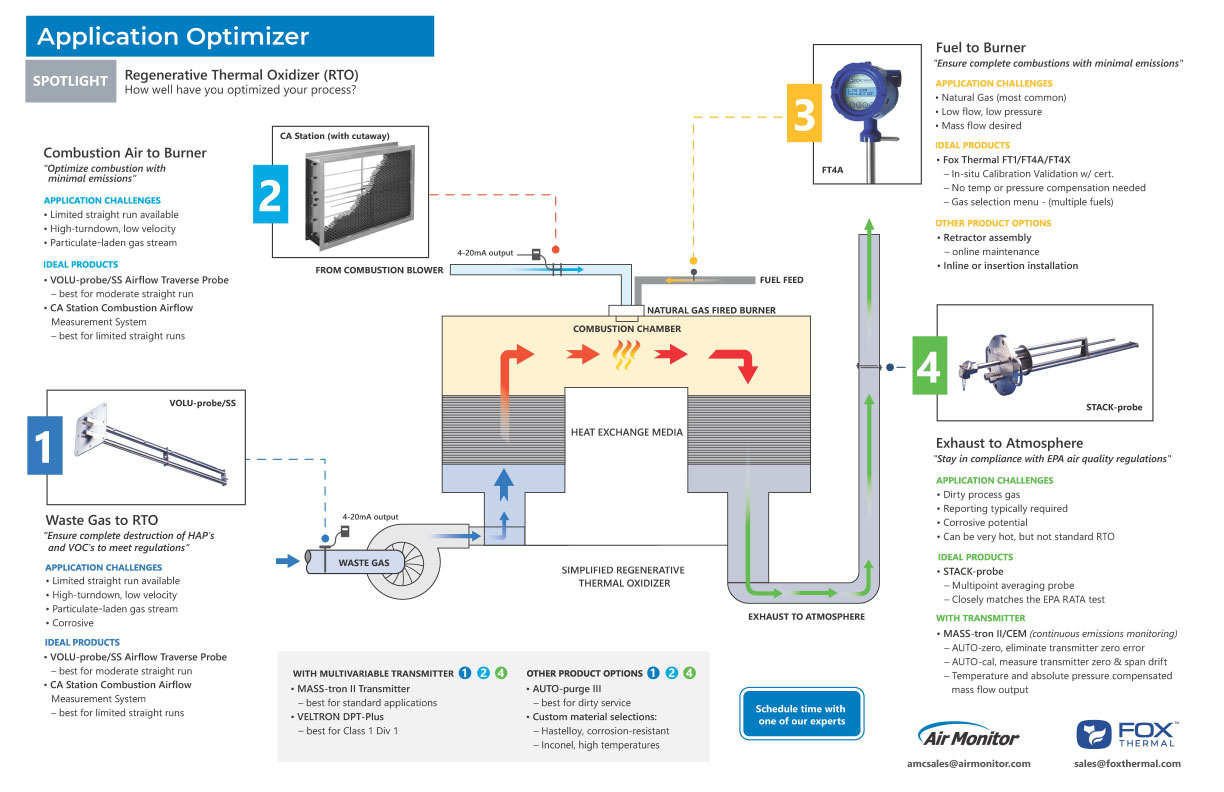

In this scheme, flow measurement devices are added for both fuel and air flow measurement to provide instant feedback for maintaining the air-to-fuel ratio at its most efficient point. In a fully metered system, accurate mass-based airflow measurement is crucial.

The rationale behind fully metered systems is to address multiple issues simultaneously: promote efficient fuel use, control emissions, extend burner lifetime (especially with ultralow-NOx burners), and expand the efficient operating range. Fully metered systems typically include O2 trim, as well. This provides the ultimate in control and final operation.

Advanced Control Technology for Increased Efficiency

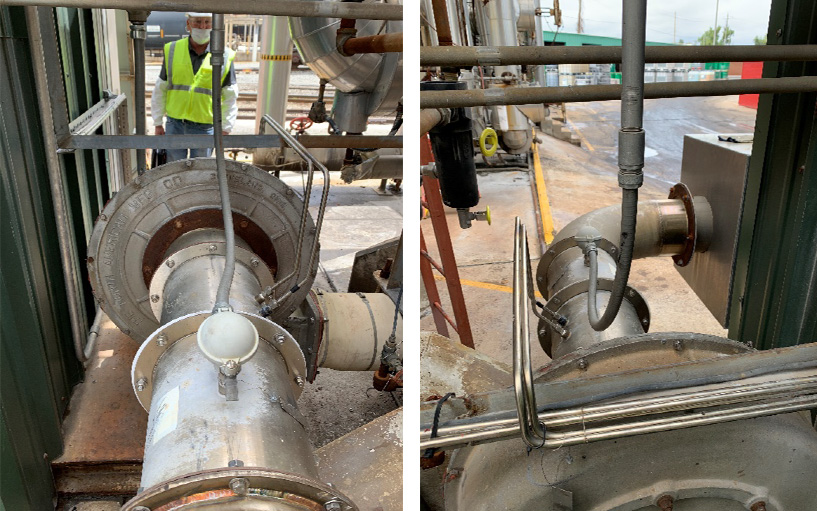

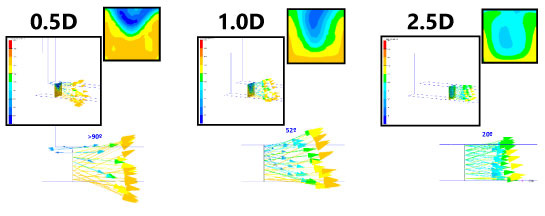

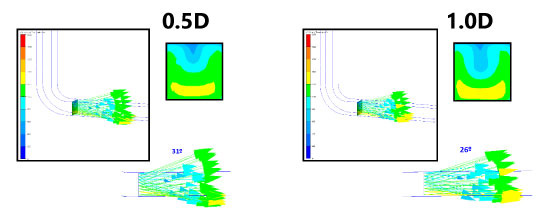

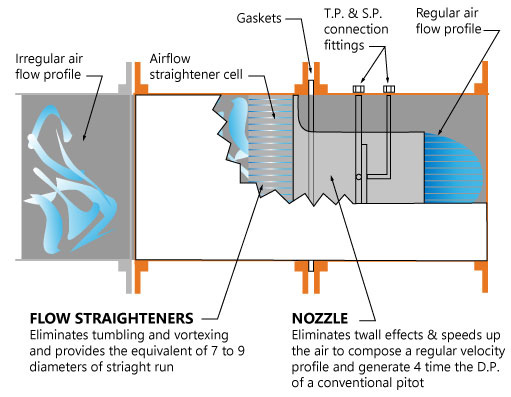

The fully metered combustion control system is only as good as the measurement technologies used as inputs. These can include flow conditioners followed by multipoint Pitot averaging arrays that are used to accurately sense the stratified velocity profile.

Next, a low-range multivariable transmitter is used to amplify the differential pressure and compensate for changes in atmospheric pressure, static pressure, and process temperature. This provides a 4–20mA output with a linear relationship to mass flow to the fully metered control system.

In cases where particulates are present, an automatic purge system also is integrated into the flow measurement system, ensuring that the measurement is never lost due to the sensing ports plugging. During this purge cycle, the signals are held at their last values.

Benefits of Fully Metered Combustion Control Systems

The degree of actual control enabled with a PP/O2 trim system is not very large. In contrast, state-of-the-art fully metered systems have the best ability to optimize the efficiency of burners and can address multiple challenges at once, including efficiency, maintenance, safety, and emissions.

Fully metered systems allow tighter control of the air-fuel ratio throughout the full operating range of the boiler and ensure that emissions are within specifications. They also allow a much higher degree of control for operations over tuning the system, so operators can closely match the optimal air-fuel ratio even throughout process temperature swings, barometric pressure, and static pressure changes.

The greater degree of combustion air control means there are fewer boiler trips, so less downtime across full operating ranges of the combustion burner when the air-fuel ratio gets out of balance. Fully metered systems also can easily adapt to fuel type or composition changes such as switching between natural gas and fuel oil or changing natural gas suppliers.

The challenge of realizing fuel savings while maintaining the ideal air-to-fuel ratio for process controls is felt by plant managers everywhere. Discover more information about Air Monitor’s combustion air flow measurement technologies and how they can benefit your industrial boiler application by clicking below.