Get Cost Savings with an Optimized Thermal Oxidizer in your Facility

The Importance of Thermal Oxidizers in Industrial Processes

Thermal Oxidizers can be found in a variety of industrial facilities and are used to process industrial waste streams before venting to the atmosphere. Specifically, they are used to remove volatile organic compounds (VOC’s) and other hazardous air pollutants (HAP’s) from process exhaust flows as required by the EPA/Clean Air Act.

How it Works

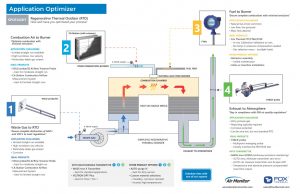

The waste gas containing the pollutants is fed into the thermal oxidizer. The combustion chamber within the thermal oxidizer must reach the targeted operating temperature to destroy the pollutants in the chamber. A burner is used to achieve the targeted temperature, so the combustion air and fuel feeding the burner must be tuned to the optimal air-fuel ratio to run efficiently. If the targeted operating temperature is maintained, the pollutants are destroyed through thermal combustion and are chemically oxidized to form exhaust gas comprised of CO2 and H2O. The exhaust gas is then vented to atmosphere.

Types of Thermal Oxidizers

Thermal oxidizer technologies include:

- Direct fired thermal oxidizer – afterburner

- Regenerative thermal oxidizer (RTO)

- Direct fired with heat recovery (recuperative thermal oxidizer)

- Flameless thermal oxidizer

- Catalytic oxidizers (regenerative or recuperative

4 Key Ways to Optimize

Air Monitor has identified 4 key measurement points to optimize thermal oxidizers in the new Application Optimizer document. Download your copy of the Air Monitor Application Optimizer for Thermal Oxidizers to learn how to optimize your process now.