Air Monitor has released the new Application Optimizer for Process Heaters.

The Importance of Process Heaters in Industrial Processes

Process heaters are used for a variety of purposes across many different industries. Power plants, manufacturing facilities, automotive plants, and the oil and gas industry are some examples where process heating is required for the preparation or treatment of materials as part of a larger process to create or manufacture something.

How Process Heaters Work

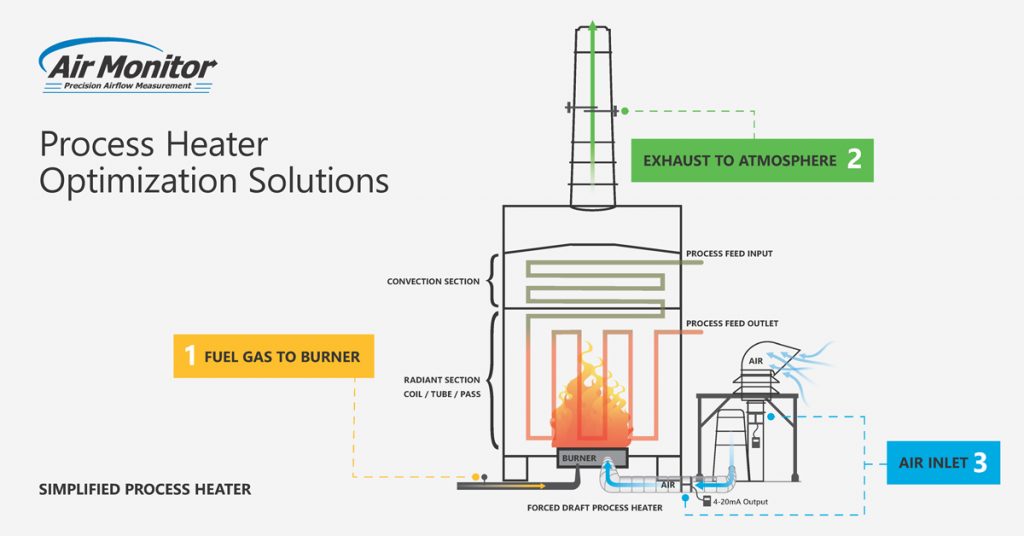

Natural gas, fuel gas, and/or oil are supplied to burners at the base of the gas-fired process heater. To achieve combustion, air is fed to the burners through a natural, induced, forced, or balanced draft. Combustion occurs in the radiant section where coils or tubes traverse from the convection section of the heater. The process fluid enters the tubes or coils through the process feed inlet, is heated to a desired temperature, and exits the heater through the process feed outlet.

Optimizing your Process Heater – 3 Key Measurements

Monitoring combustion airflow and fuel gas flow to the Process Heater is essential to gaining insight on how to optimize the process. This new Application Optimizer identifies key flow measurement points on Process Heaters that will help users tune to the optimal air/fuel ratio to achieve efficient combustion. A more efficient heater will result in cost-savings and the opportunity to minimize emissions.

Download the Application Optimizer for Process Heaters

Get your copy of the new Application Optimizer for Process Heaters from Air Monitor to learn more about how to optimize your process heater today!

Get the Application Optimizer for Process Heaters >>

Air Monitor Solutions

Air Monitor airflow measurement stations provide higher accuracy over shorter lengths of straight duct than competing products. This is achieved by using multi-point averaging pitot tube technology coupled with ultra-low, highly accurate, differential pressure measurement. Another benefit of Air Monitor equipment is the ease with which it can be applied to existing systems. This is feasible with minimal disruption and downtime.