Combustion Air Flow Measurement

Stop wasting money and fuel on inefficient and outdated air flow control systems for your industrial kilns, smelters, ovens, and similar applications that may overfeed combustion air by up to 20 percent.

Millions of dollars are wasted every day in combustion processes in the power and co-generation industries: as a result of insidious combustion losses. Your processes may be operating normally while hiding operation inefficiencies wasting large amounts of excess oxygen or fuel that can’t be easily identified.

For significant savings on the cost of fuel and additional maintenance associated with blower or burner wear, consider upgrading combustion air flow meters or installing an instrumented monitoring system from Air Monitor.

We can help you

Lower operating costs with combustion control systems

For industrial processes requiring extremely high temperatures, fuel costs can become burdensome. Achieving combustion optimization in burner equipment with airflow measurement devices from Air Monitor will lower operating costs by increasing combustion efficiency and improving emissions.Maximize burner combustion efficiency

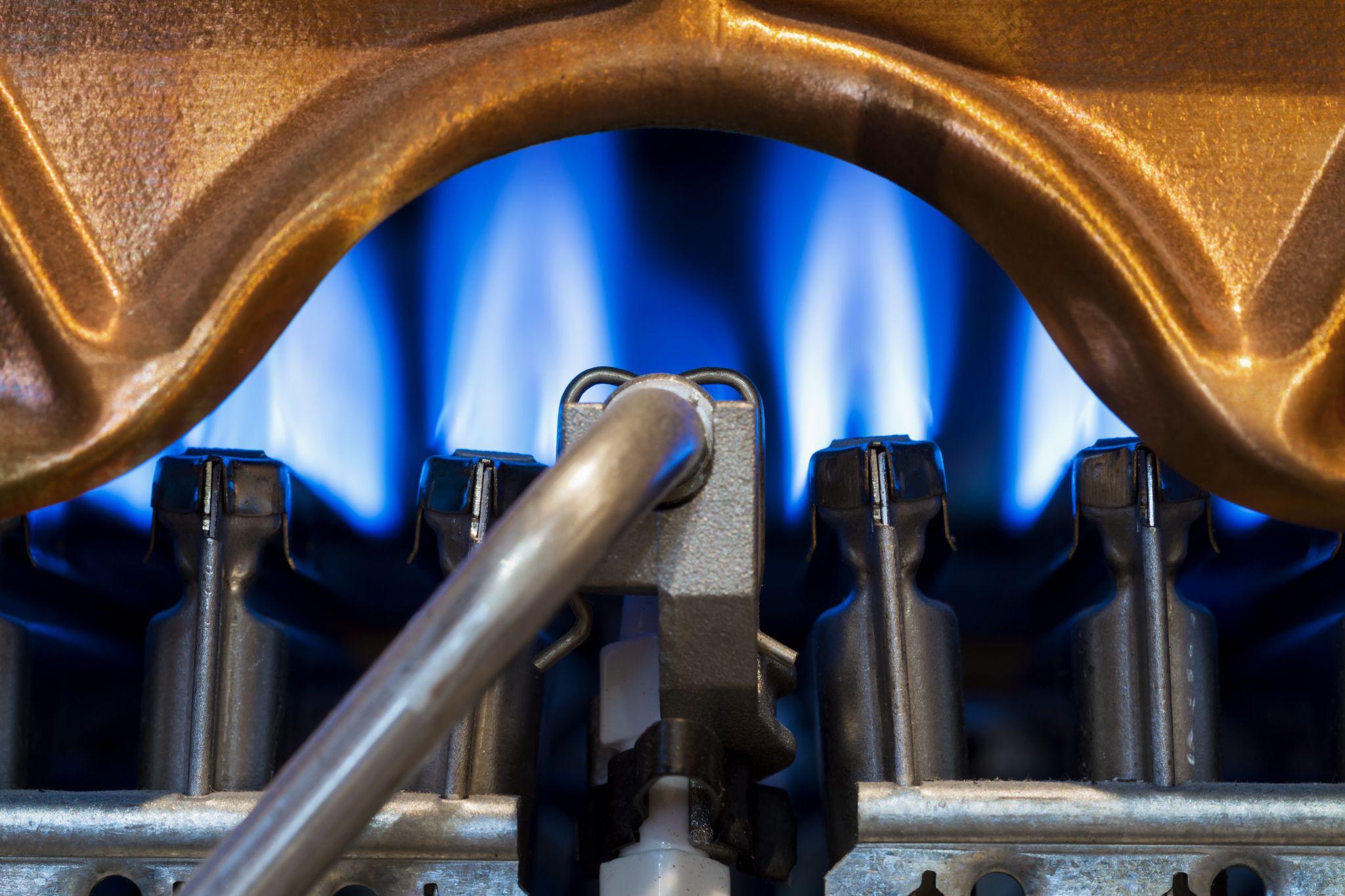

Measuring flow rates into the combustion chamber is necessary to achieve the perfect air-to-fuel ratio to prevent running too lean or too rich. Stop dealing with underperforming boilers and fix incomplete combustion with airflow management systems by Air Monitor.Optimize emissions from natural gas-fired boilers

Although natural gas processes tend to burn cleaner than other fuel types, these boilers may still encounter particulate-laden airflows subject to emissions regulations. They often lack accurate instrumentation and control systems to ensure the combustion air flow and natural gas flow are tuned to the optimal air-to-fuel ratio.Combustion Airflow Measurement Applications

A variety of equipment used in industrial applications like boilers, furnaces, regenerative thermal oxidizers (RTOs), burners, etc. are tuned with an optimal air-to-fuel ratio to improve efficiency and achieve an ideal combustion process. Measuring airflow is key to finding this ratio and avoiding incomplete combustion. An optimized system will also result in less maintenance costs over time.

Natural Gas-Fired Industrial Boilers and Package Boilers

Although natural gas processes tend to burn cleaner than other fuel types, boilers may encounter particulate-laden airflows and be subject to emissions regulations when exhausted to the atmosphere. They often lack the instrumentation required to accurately measure the combustion flow of air and natural gas needed to tune the optimal air-to-fuel ratio. Find out more in our Application Optimizer.Power, Biomass, and Recovery Boilers

Regardless of the fuel type used to power the boiler, measuring airflow into the combustion chamber is necessary to calculate the perfect air-to-fuel ratio. A system that is running too lean or too rich results in either performance or cost issues. There are also emissions issues caused by poor burner design or poor combustion.

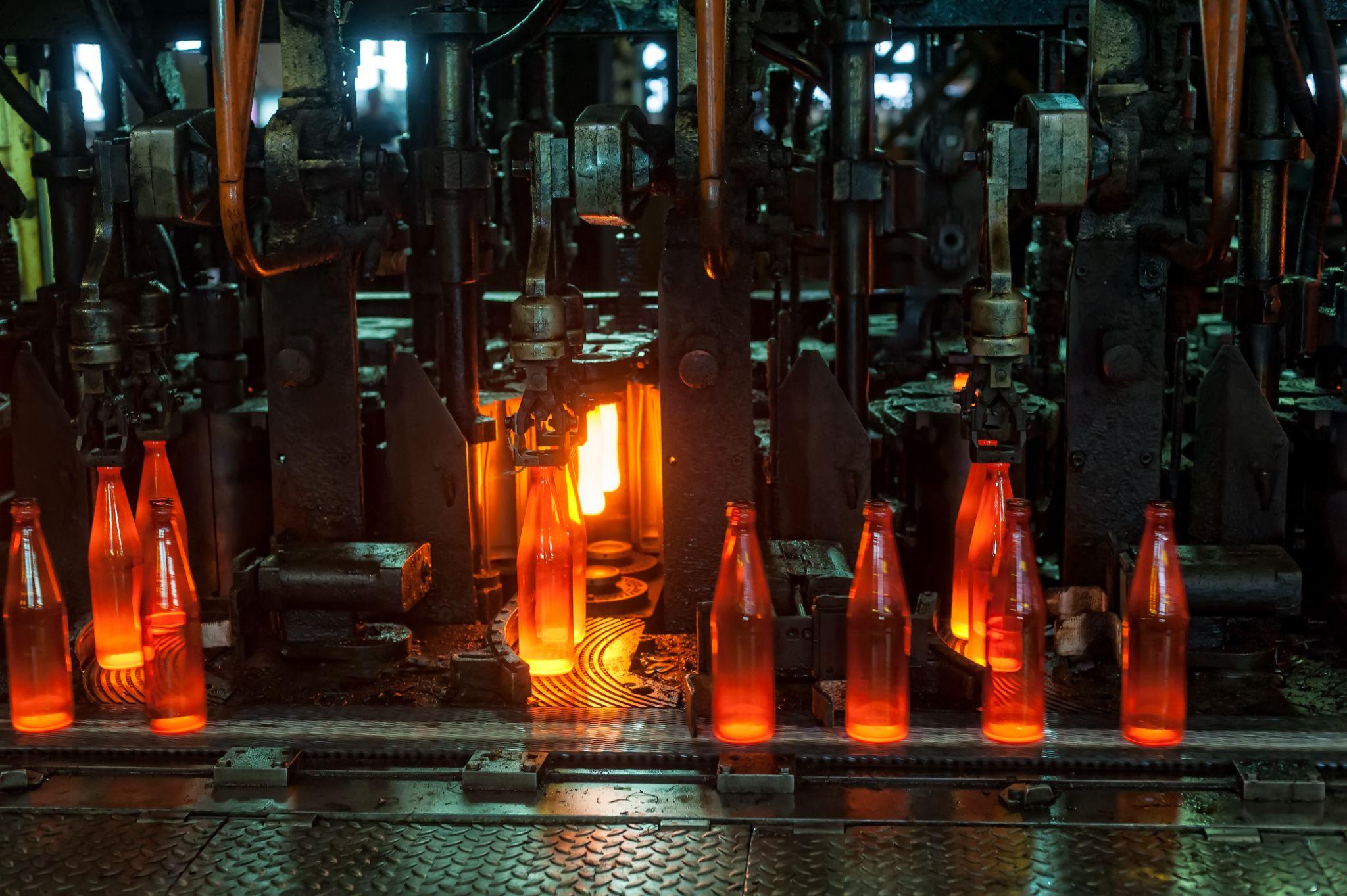

Heaters, Furnaces, Ovens, and Kilns

Whether for ceramics and glass or annealing and debinding, the industrial sector relies on heat from a variety of burner equipment to perform essential functions. With some processes requiring extremely high temperatures, fuel costs can become burdensome. Achieving combustion optimization of burner equipment with air flow meters will lower operating costs by increasing efficiencies and improving emissions.News & Innovation

The Importance of Straight, Unobstructed Pipe Runs in Air Flow Measurement

The biggest challenge in air flow monitoring applications is obstructions causing turbulent or irregular airflow profiles in the desired straight run section.Optimization 101: Natural Gas-Fired Boiler Efficiencies

Some natural gas-fired industrial boilers have a relatively clean airflow combustion process, but particulate-laden airflow is common and creates challenges for most flow measurement devices on the market.Exploring the Top 3 Industrial Benefits of Facility Pressure Control

Of all the things hitting your desk, why should you worry about space pressure control in your facility? We’ve researched for you and have identified three major benefits.Applications

Chemical Plants

Chemical plants use combustion air monitoring devices to optimize combustion control and combustion efficiency. Accurate combustion air flow measurement is the first step towards minimizing unburnt carbon, controlling excess air, and eliminating harmful emissions.

Refineries

By fully metering combustion fuel and air flows, refineries increase efficiencies, improve safety, and reduce emissions for the industrial boilers, fired heaters, RTOs, and burners used in the petroleum refinement processes for the oil and gas industry.

Carbon Black Facilities

Off-gases from the cracking process are sent to RTOs and waste heat boilers for destruction, to generate energy, and to meet air quality standards. Getting RTOs and boilers operating at peak efficiency requires accurate combustion air, fuel flow, and tail gas flow measurement.

Sugar Refineries

Recycling by-products lead sugar refineries to optimization gains by utilizing the remnants of the sugar refining process or bagasse as a fuel to a biomass boiler.

Paper & Pulp Boilers

Pulp & paper manufacturing transforms raw materials like wood chips into paper. Airflow measurement is a key component. Combustion optimization and boiler system control for black liquor and bark furnaces ensure an efficient and fine-tuned cook during the kraft process.