Carbon Black Manufacturing

Air Monitor can help carbon black manufacturers optimize production and minimize emissions with accurate, reliable combustion air flow measurement equipment.Carbon black manufacturing processes use combustion air monitoring devices to optimize combustion control and combustion efficiency of waste heat boilers and RTOs. Accurately measured tail gas flow and combustion air flow can help operators minimize unburnt carbon, control excess air, and eliminate harmful emissions.

Speak With an Application Engineer

Measurement accuracy in limited straight runs

Combustion airflow measurement technology must be able to handle the velocity profile stratification common to short runs of duct, even for the larger duct sizes often found in carbon black production facilities. Air Monitor’s Combustion Air (CA) Station ensures that air flow and tail gas flow can be accurately measured in limited straight duct runs.Maintain accuracy over a broad velocity range

The broad operational range of combustion air flow and tail gas flow often results in very low velocities, particularly at minimum load. The technology for flow measurement must be accurate throughout this range. Air Monitor’s VELTRON DPT-Plus, with its high level of accuracy, can maintain linear output signals on applications requiring velocity or pressure turndown of 5:1.Automatically keep sensing ports clean

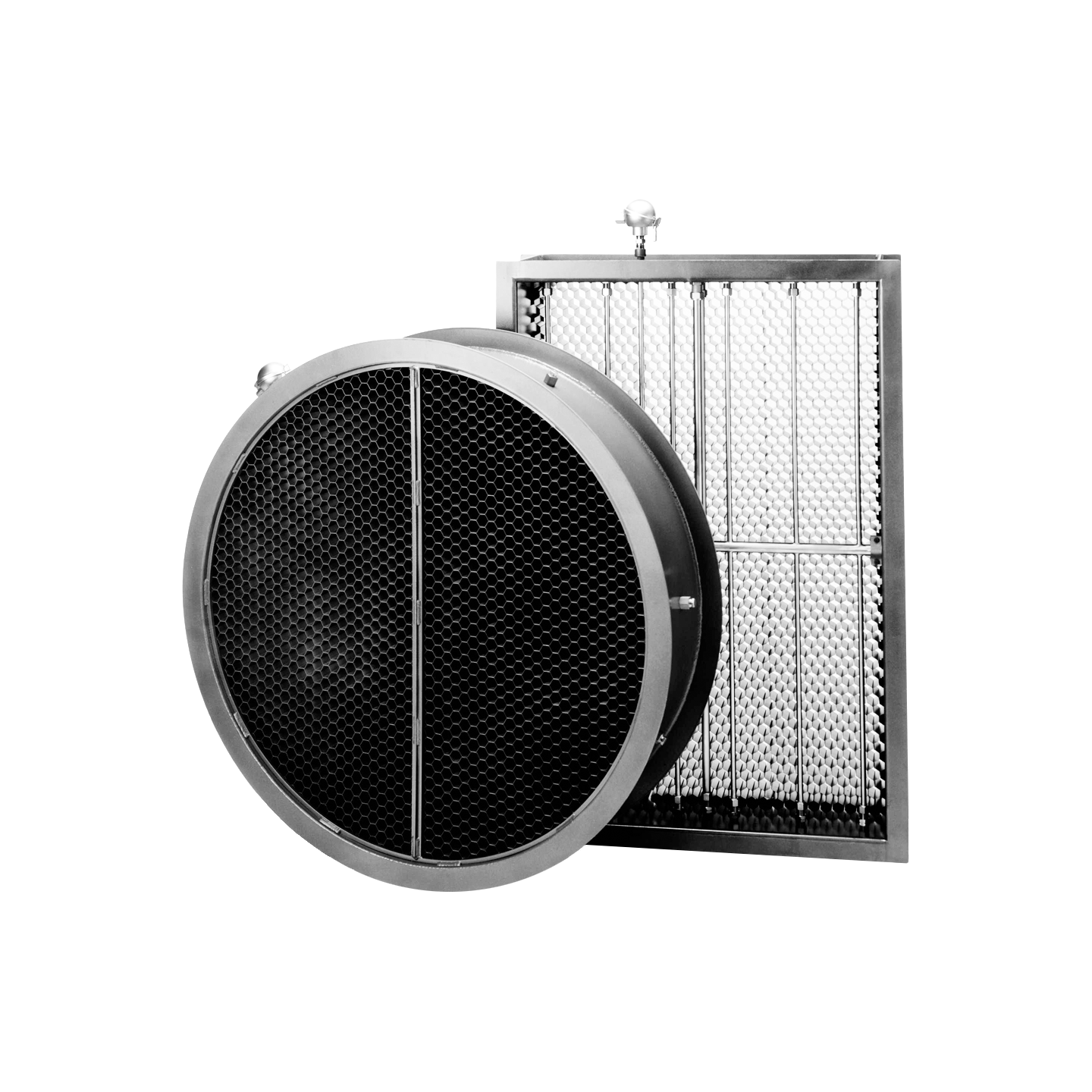

In carbon black production, combustion air and tail gas contaminated with particulates can plug the sensing ports on a DP air flow measurement device or coat the RTDs on a thermal mass flow measurement system. Air Monitor’s high-pressure AUTO-purge III technology is a proven method to keep the sensing ports clean and maintain the accuracy of the measurement system.AUTO-Purge lll

The AUTO-purge III is designed for high temperature, dirty airflow applications such as tail gas from carbon black cracking, one of the dirtiest and most difficult gases to measure. In cases where continuous exposure to airborne particulates that might impair the accuracy of our Combustion Air Station (CA Station) or our VOLU-probe/SS array, a periodic purging with high-pressure high-volume air assists in clearing the sensing ports of the total and static pressure manifolds.

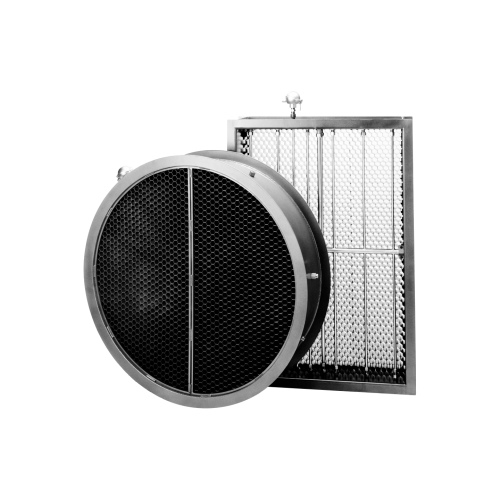

CA Station - Combustion Airflow Measurement Station

Air Monitor’s ruggedly constructed CA (Combustion Air) Station, with integral airflow processing cell and Fechheimer-Pitot measurement technology, is engineered to meet the challenging operating conditions in the carbon black production process, such as limited straight runs, dirty and heavy particulate matter, high temperatures, and wide variations in composition.

CAMS™ - Combustion Airflow Management System

CAMS™ provides a reliable and accurate means of measuring airflow and tail gas flow in carbon black production. Combined into a single-engineered package are the CAMM™ – Combustion Airflow Management Module and the AUTO-purge III to protect against airborne dust and particulate matter so prevalent in RTOs and boilers used in carbon black manufacturing.

VOLU-probe SS – Stainless Steel Traverse Probe with Transmitter

The VOLU-probe/SS is ideal for harsh, particulate-laden applications, such as carbon black manufacturing. It consists of multiple Pitot total and static pressure sensing ports positioned along the length of each probe to traverse the duct cross-section. They average the sensed pressures in the internal manifolds and provide velocity pressure measurement accurate to within 2-3%.

ACCU-flo High Accuracy Stainless Steel Station

This flow measurement station with flow conditioner provides high accuracy (±0.5%) measurement for process monitoring and combustion control systems when combined with an ultra-high accuracy mass flow transmitter, such as Air Monitor’s VELTRON DPT-Plus. The combination of the integral flow straightener cell with the nozzle means little or no upstream straight run is needed to achieve high accuracy.

VELTRON DPT-Plus

This mass flow transmitter receives flow signals (total and static pressure) from a combustion airflow measurement station or probe array, internally performs density correction for the process temperature, and produces individual outputs for standard air volume or mass flow and temperature. All transmitter parameter settings, zero and span calibration, and display scaling are performed digitally in the onboard microprocessor.

More About Carbon Black Manufacturing

Off-gases from the carbon black cracking process are sent to regenerative thermal oxidizers and waste heat boilers for destruction, to generate energy, and to meet air quality standards.

Larger duct sizes in the production process result in fewer diameters of straight run. The tail gas is measured prior to entering the RTO or boiler and is typically in the vicinity of a modulating valve, tee, or elbow. The measurement devices chosen must be able to handle the resulting velocity profile stratification common to short runs of duct and sometimes damper modulation as well.

Find out more about how Air Monitor can help your carbon black manufacturing processes achieve efficiency, safety, and emissions goals.