Turbulent Flow

The biggest challenge in air flow monitoring applications are obstructions causing turbulent or irregular airflow profiles in the desired straight run section. Most air flow measuring devices are adversely affected by an underdeveloped flow profile. Ideally, more straight run is added in to the length of duct or pipe where an air flow measurement device is needed to achieve the best accuracy.

Airflow Dynamics

Let’s look at the foundation of airflow dynamics in air flow measurement to understand how straight run lengths affect the flow/velocity profiles in air ducts or industrial pipes.

- Airflow is extremely dynamic

- Velocity profiles can shift based on proximity to upstream/ downstream disturbance and/or the airflow velocity

- Accurate measurement requires multiple sensing points across measurement plane

- The more points of measurement, the better the measurement accuracy

The type of obstruction or elbow in the duct/pipe, the velocity, and other factors will have differing effects on the velocity profile at different distances.

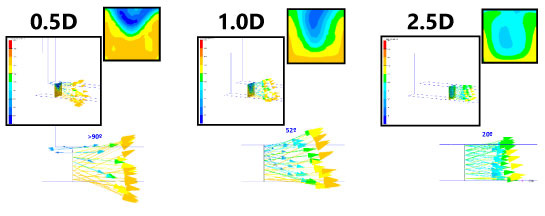

90 Degree Elbow

The images below show how a duct’s airflow velocity profile is affected by a 90 degree elbow without vanes. The closer the airflow measurement is to an elbow, the more turbulent it becomes. As shown, increasing the distance from 0.5 to 2.5 diameters produces a much more uniform airflow condition.

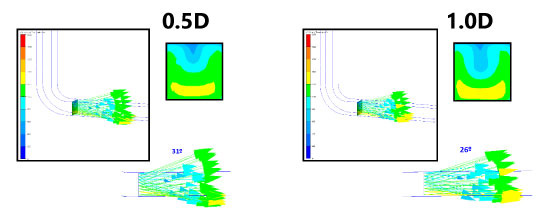

Sweep Elbow

Of equal importance are the directional vectors of the airflow in a duct. The images below show how additional straight run downstream of a sweep elbow will develop the flow profile, so that angle of flow within a duct is improved. Many airflow technologies are susceptible to large errors with only minor angular flow components (<10 degrees).

Getting the Right Fit in a Tight Spot

Depending on the technology, the straight run requirements may be excessively long considering the installation location. What do you do when you can’t add duct or pipe lengths to accommodate air flow measuring technologies with excessively long straight run requirements? You find a technology that can accommodate the shorter straight runs by calling the Air Monitor experts.

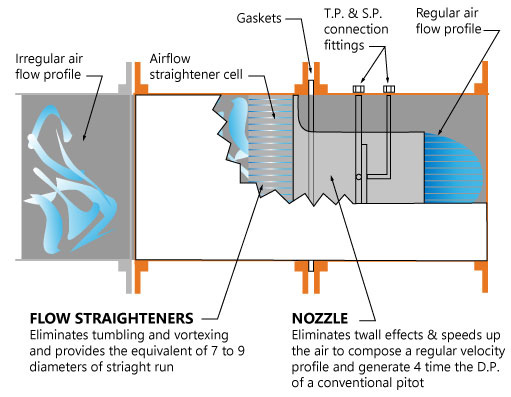

The ACCU-flo in Action

Air Monitor manufactures airflow measuring stations, like the ACCU-flo, that have built-in flow straightening and profile conditioning technology.

This flow straightening technology is paired with a profile conditioner and air flow measuring probes that are engineered to function accurately in the specific airflow conditions in the duct.

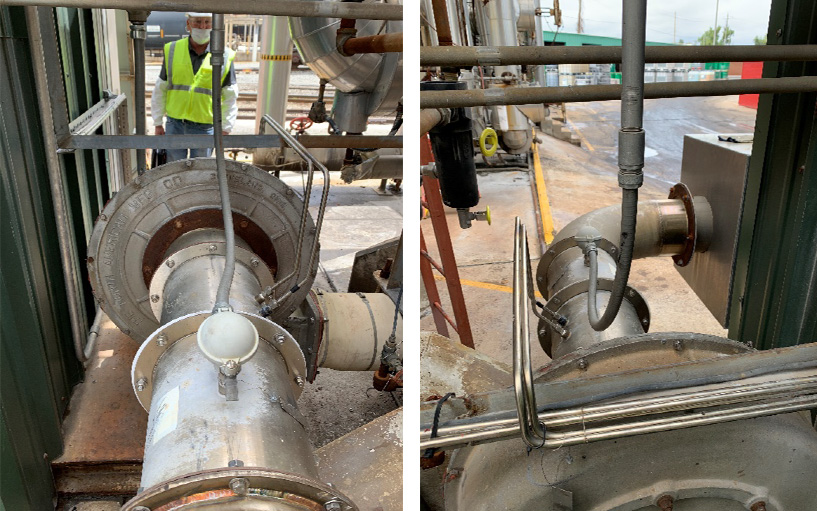

Here are two examples of the ACCU-flo installed and accurately measuring airflow and temperature for regenerative thermal oxidizers (RTOs) with limited straight runs available:

The client – and the measurement point – were in a tight spot. Luckily, the ACCU-flo was able to straighten the flow of air in the pipe and offer a truly accurate measurement. The resulting measurements allowed the client to fine tune the airflow to improve the efficiency of the RTO for big savings.

For more information on how Air Monitor products can help in your application, contact one of our experts today!