Paper & Pulp Mills

Pulp and paper manufacturing is a multi-step process that takes raw material such as wood chips from trees and transforms it into paper fit for everyday use in schools and businesses or cardboard for shipping products worldwide. Combustion air flow measurement is a key part of several equipment functions in pulp and paper mills.

Air Monitor Corporation provides air flow measuring stations and air flow measuring devices for the most challenging pulp and paper manufacturing applications, including clean & dirty airflow, combustion control airflow, and pressure measurement. Our team has decades’ worth of combined experience, and we match our best-in-class technology and air flow measurement devices with best-in-class technical support.

We can help you

Reduce fuel cost

Pulp and paper mills are energy intensive. Excessive energy consumption in the drying process is a concern due to rising energy prices. With combustion air flow measurement systems from Air Monitor, you can fine-tune your processes while minimizing the need for natural gas.Increase combustion efficiency and productivity

Combustion control airflow management systems in pulp and paper boilers can increase productivity, reduce the need for cleaning shutdowns and minimize toxic emissions.Precisely control air in pulp and paper drying systems

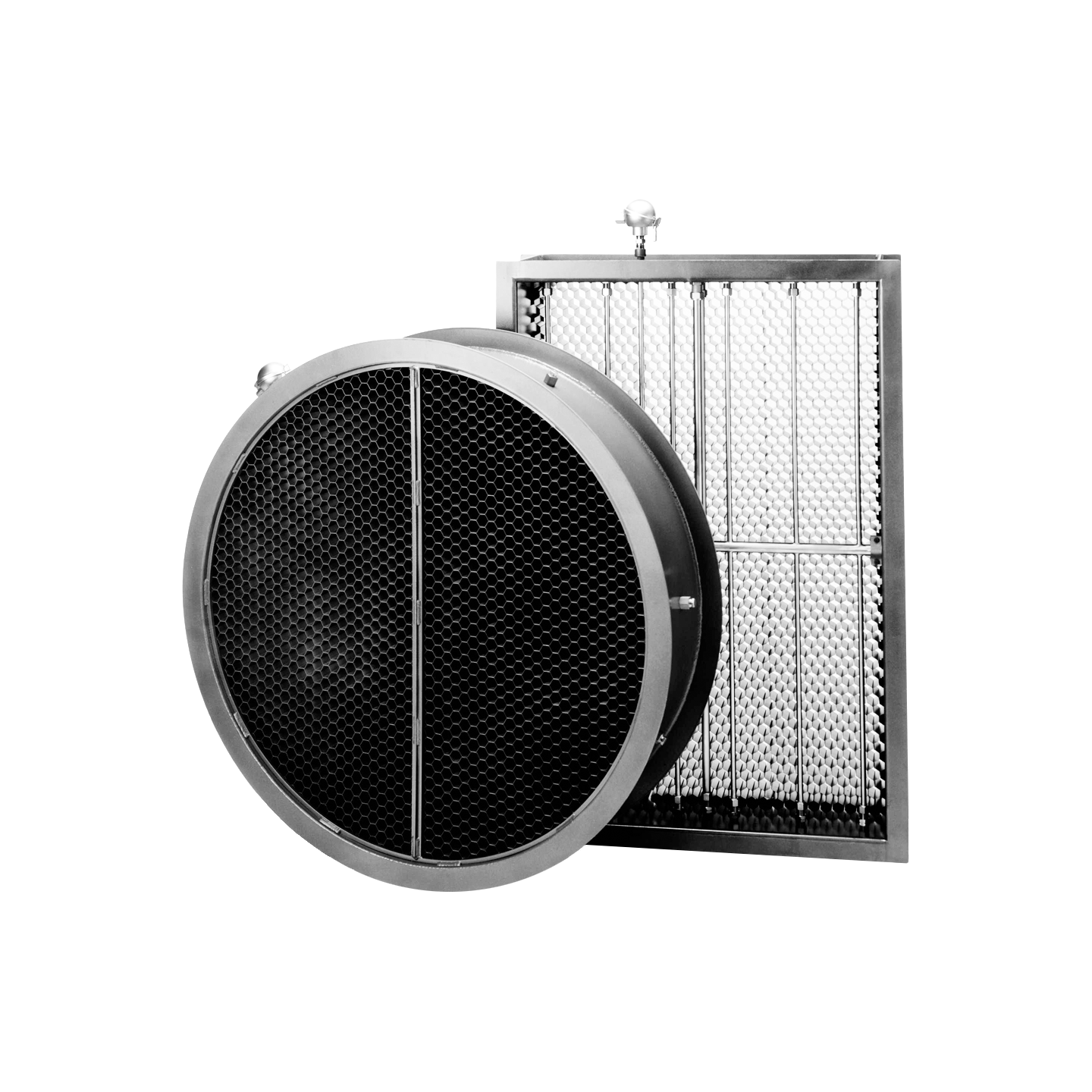

In paper manufacture, machine dryer hood air systems require precise airflow control for efficient coating dryers and wood drying, reducing the need for steam and improving the evaporation rate.Auto Purge lll

Air Monitor’s AUTO-purge III is designed for dirty airflow applications and recovery boilers, where continuous exposure to airborne particulates might impair the measurement accuracy of our Combustion Air Station (CA Station) or our VOLU-probe/SS array. When activated by one of our “smart” flow transmitters or a distributed control system, a periodic purging with high-pressure high-volume air assists in maintaining the sensing ports of the total and static pressure manifolds in a clear unobstructed condition.

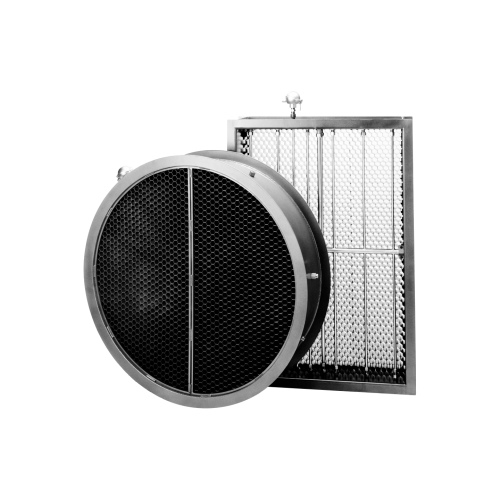

CA Station - Combustion Airflow Measurement Station

Air Monitor’s ruggedly constructed Combustion Air (CA) Station, with both integral airflow processing cell and FechheimerPitot measurement technology, is engineered to meet the challenging operating conditions in pulp and paper manufacturing processes, such as black liquor recovery boilers and paper drying.

CAMS™ - Combustion Airflow Management System

The Combustion Airflow Management System is designed to fulfill the need for a reliable and accurate means of flow measurement in applications including paper drying and recovery boilers. Combined into a single engineered package are the CAMM™ – Combustion Airflow Management Module – containing the microprocessor-based instrumentation to measure the airflow and manage the purge cycle, and AUTO-purge to protect against any degradation in performance due to the presence of airborne particulates.

VOLU-probe SS – Stainless Steel Traverse Probe with Transmitter

The VOLU-probe/SS Stainless Steel Airflow Traverse Probe is ideal for clean or harsh and particulate-laden applications such as flue gas recovery. It consists of multiple Pitot total and static pressure sensing ports positioned along the length of each probe to traverse the duct cross-section. They average the sensed pressures in their separate internal manifolds and provide velocity pressure measurement accurate to within 2-3% of actual flow.

More About Paper & Pulp Mills Applications: Black Liquor Boilers

According to the DOE’s National Energy Technology Institute, “one third of all pulping mills in the United States produce 6 million lbs/day of black liquor each.” This liquor contains a significant amount of biomass waste that can be burned in a recovery boiler to generate steam. For even greater efficiency, feeding the black liquor into a high-pressure gasifier can provide both steam and some of the electricity required by the pulping plant.

Pulp and paper boilers can have three or more combustion air flow streams (Primary, Secondary, and Tertiary) — some of which are preheated prior to entering the boiler. Excess oxygen or excess oxygen in the wrong place can reduce boiler capacity, waste fuel, increase TRS and other environmental emissions, and coat and plug the boiler. Maintaining these air flows in the proper ratio is important to maximize capacity, ensure economical operation, reduce environmental impact, and minimize the number of shutdowns for cleaning.

Flow meters and combustion control systems from Air Monitor can measure and control these streams more accurately and reliably. Our systems can provide more information regarding mass flow distribution while also providing significant economic payback by:

- Increasing black liquor firing rate closer to the rated capacity of the unit

- Reducing the number of multi-day shutdowns for cleaning

- Reducing the number and amount of fines for environmental emissions