Pharmaceutical Manufacturing

Maximize production efficiency and control – and ultimately product quality – with precise and accurate airflow measurements for controlling fluidized beds, rotary drums, flash dryers, kilns, and similar processes in the pharmaceutical industry.

Air Monitor products have been designed specifically to help improve the reliability of air flow systems by improving their accuracy over a wide range of flow rates. This can improve process quality and product consistency, increase production rates, and reduce maintenance costs and downtime in the drug manufacturing process.

Speak With an Application Engineer

Air Monitor Solutions Can Help

Avoid Plugging & Coating of Equipment

Airflow measurements from process equipment can provide significant operational benefits. When the air flow includes particulate matter, accurate measurement is more difficult. Traditional meters can become coated and plugged. Plugging and coating can be mitigated by incorporating an Air Monitor AUTO-purge III that periodically clears the flow meter sensing elements with clean compressed air to ensure reliable flow measurement when particulate matter is present.Maintain Accuracy and Product Validation

Airflow devices incorporated into pharmaceutical process equipment with short upstream and downstream straight pipe runs can increase inaccuracies. Air Monitor’s advanced technology allows more accurate measurements for equipment with limited straight runs, while also helping to maintain accuracy over a wide operating range. These advantages make Air Monitor the go-to source for airflow measurement systems in the pharmaceutical industry.Improve Product Quality and Efficiency

The FDA’s regulatory standard for ensuring pharmaceutical quality is the Current Good Manufacturing Practice (CGMP). The CGMP approval process requires that drug companies adequately control their manufacturing operations. In validated industries such as pharmaceuticals, precise control of airflow and air temperature with the help of flow devices from Air Monitor, can help maintain high product quality, reduce waste, and increase uptime.AUTO-purge III

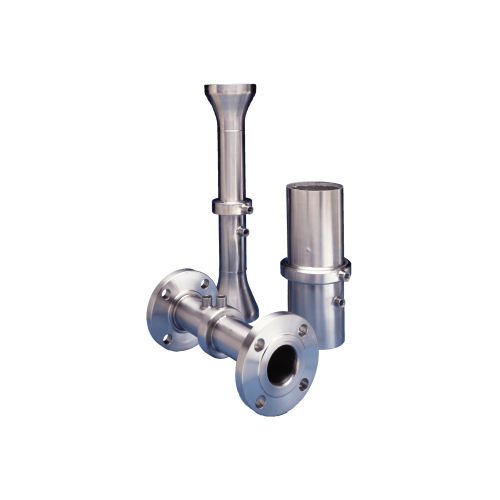

Plugging and coating of airflow measurement systems can be mitigated by incorporating an Air Monitor AUTO-purge III that periodically clears the flow meter sensing elements with clean compressed air. This ensures reliable flow meter operation when particulate matter is present.

Applications in the pharmaceutical industry include kilns, fired heaters, pneumatic conveyors, and dust collection systems.

ACCU-flo High Accuracy Stainless Steel Station

The Air Monitor ACCU-flo/NP is a combination precision nozzle and multi-point, self-averaging Pitot airflow measurement station. When combined with an ultra-high accuracy transmitter, such as Air Monitor’s VELTRON II, the ACCU-flo/NP provides high accuracy (±0.5%) flow measurement for critical process monitoring and control applications, such as pharmaceutical manufacturing.

The combined effect of the integral flow straightener cell and the nozzle means little or no upstream straight run is needed to achieve the published accuracy.

LO-flo/SS Stainless Steel Pitot Traverse Probe

The LO-flo Pitot Traverse Station is a combination air equalizer-straightener with a self-averaging Pitot tube traverse station. The LO-flo is fabricated entirely of Type 316 stainless steel with all welded construction and is capable of operation up to 1000ºF.

The LO-flo provides highly accurate measurement of low air volumes of 2 to 2000 CFM for monitoring, indicating, and controlling applications when coupled with ultra-low span electronic differential pressure or flow transmitters such as the Air Monitor VELTRON II.

Applications include pneumatic conveyors, dust collection systems, quench exhaust, and fluidized bed dryers and coaters.

VOLU-probe SS – Stainless Steel Traverse Probe with Transmitter

The VOLU-probe/SS Stainless Steel Airflow Traverse Probe is ideal for clean or harsh and particulate-laden applications operating at temperatures ranging from -20 – 900°F.

It consists of multiple Pitot total and static pressure sensing ports positioned along the length of each probe to traverse the duct cross-section, providing velocity pressure measurements accurate to within 2-3% of actual flow.

Applications include clean room pressurization, quench airflow, fluidized bed dryers/coaters, and rotary drum dryers/coaters.

VELTRON II Transmitter

The VELTRON II Transmitter is an ultra-low differential pressure and flow “smart” transmitter. With its ±0.1% of natural span accuracy, it is intended for the most critical and demanding industrial applications requiring the utmost accuracy and long-term stability.

Applications in the pharmaceutical industry include pneumatic conveyors, dust collection systems, fluidized bed dryers/coaters, rotary drum dryers/coaters, clean room pressurization, product testing, and process development.

More About Pharmaceutical Manufacturing Process Quality Control

In order to adhere to the FDA’s CGMP regulations regarding the identity, strength, quality, and purity of drug products, pharmaceutical companies must be able to adequately control their manufacturing operations.

Using airflow measurement systems to monitor and control processes can help maintain drug product quality. Applications include fluidized beds, rotary drums, flash dryers, kilns, and similar processes in the life sciences and the pharmaceutical industry.

Failure of these measurement devices due to improper air and product feeds can cause issues with validation – resulting in downtime, re-validation, and loss of raw materials, products, and profits. As a result, controlling airflow through these devices is critical, and Air Monitor’s equipment is up to the challenge.